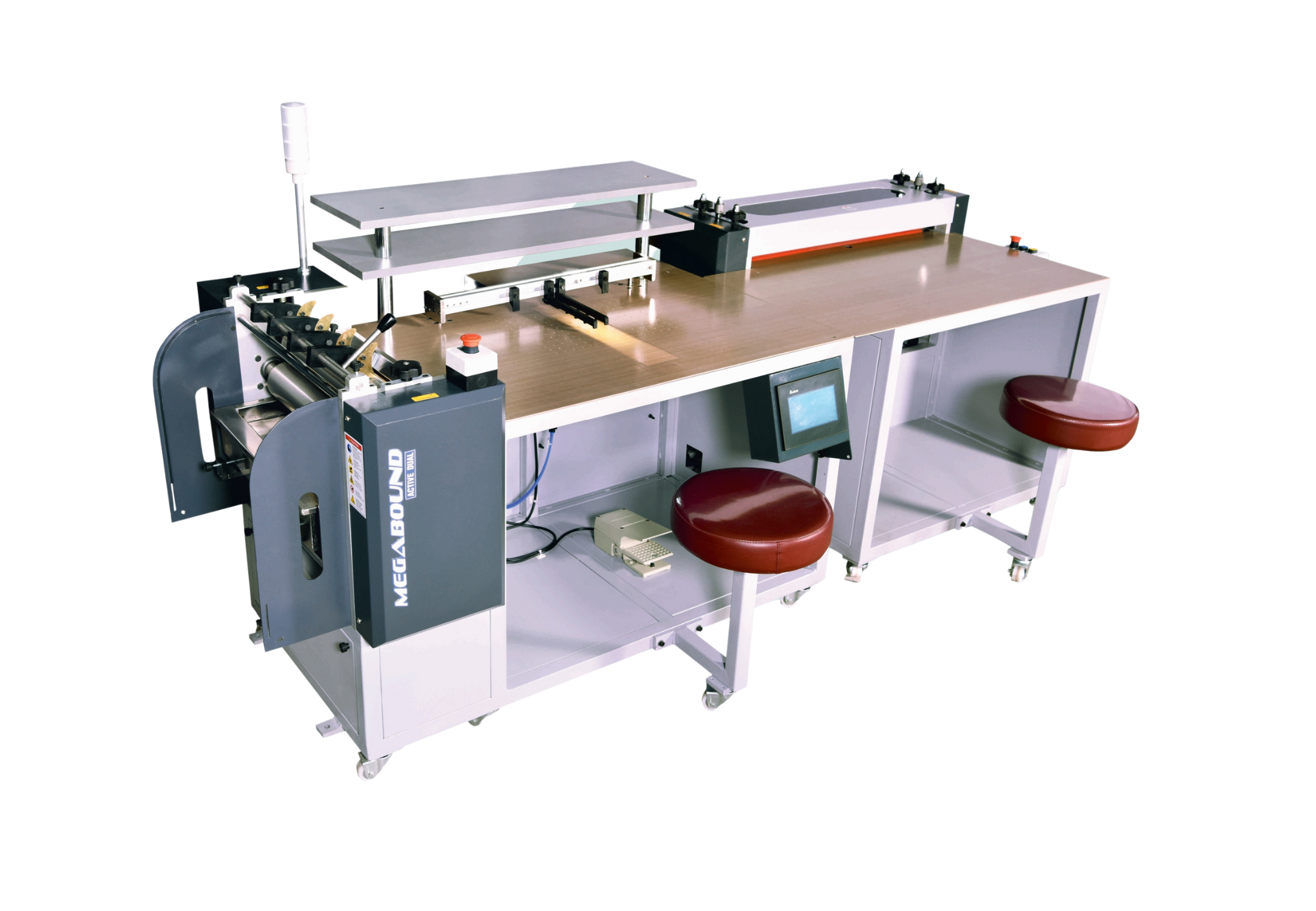

CASEMAKER ACTIVE DUAL

Our Case Maker offers seamless operation, placing control squarely in the hands of the operator stationed in front of the machine. Effortlessly guiding the cover material into the gluing unit, the operator ensures an even coating of hot gelatin glue for optimal adhesion. With intuitive foot switches, precise registration of the cover material and activation of the board register bars as effortlessly managed, facilitating accurate manual placement of board pieces.

Turning in the cover material on all four edges is achieved with remarkable efficiency, requiring just two passes by the operator. Enhanced by brush rollers and pressing rollers, this process ensures a flawless finish. Notably, our 'Active DUAL' model is equipped to handle cases with central window cut-outs, ideal for photo album production. Upon completion, the final product smoothly exits to the rear of the machine on an inclined delivery table, marking the culmination of a meticulously crafted binding process.

Active Dual Features

- Dual Operators

- No adjustment necessary for size changes

- Each cover can be of a different size.

- Cost effective, simple and reliable.

- Exceptionally wide format range

Technical Data

| Min. case size | 150mm x 160mm |

| Max. case size | 450mm x 800mm |

| Paper thickness | 80gsm - 170gsm |

| Board thickness | 1.5mm - 5mm |

| Turning-in width | 15mm - 20mm |

| Production | 5 to 8 cases/min (Approx) |

| Glue | Hot/Cold (Optional) |

| Power | 4.5HP, 3 Phase, 415 Volts |

| Dimensions | H 1025 mm x L2500 mm x W 1000 mm |

| Weight | 650 Kgs. (Approx) |

| Gluing System | Bottom |

| Man Power | Two |

| Materials | Paper, Laminated Paper, Plastic-coated Paper, Cloth, etc. |