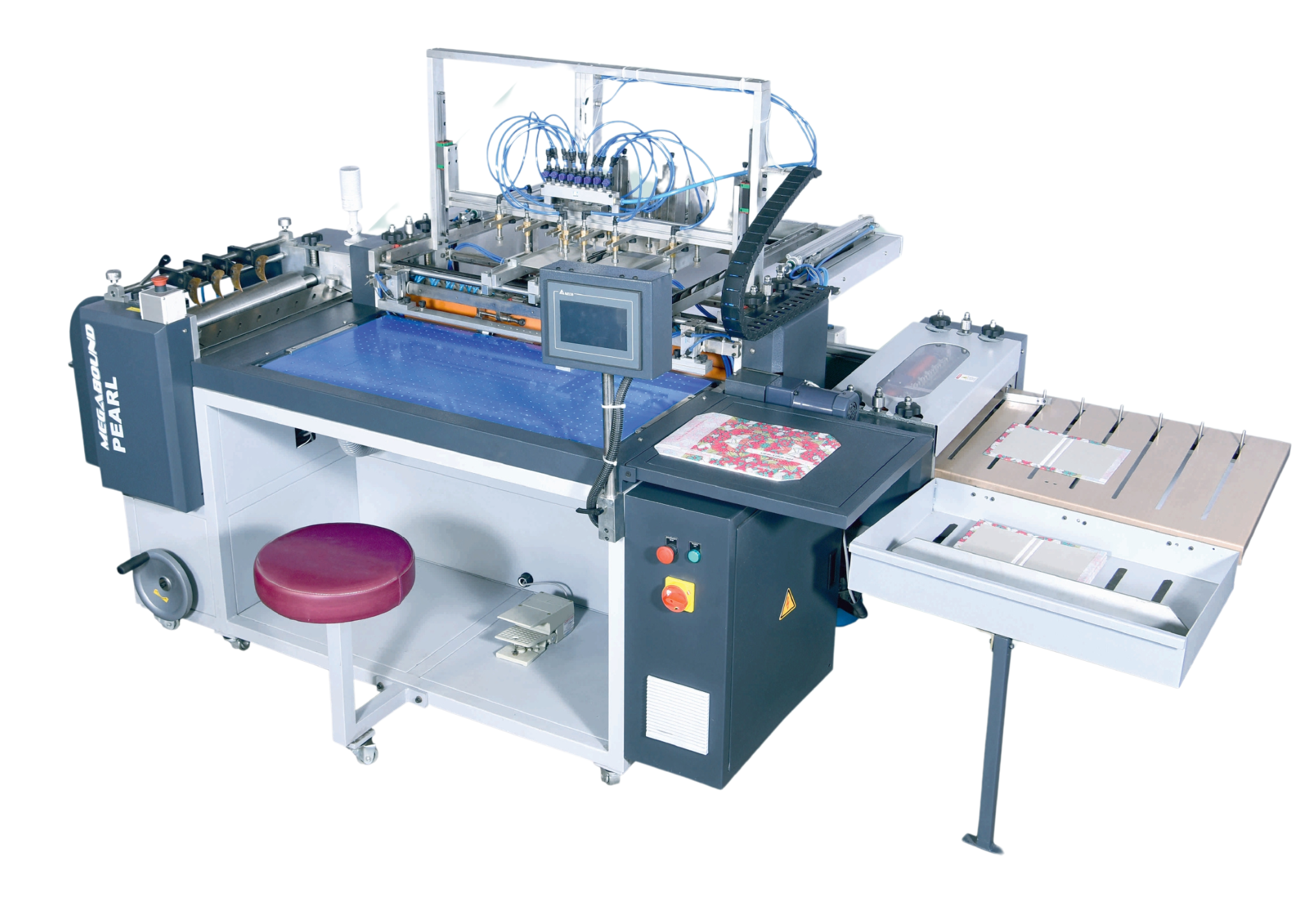

CASEMAKER PEARL

Introducing our advanced Case Maker, where every operation is seamlessly executed by the operator stationed in front of the machine. As the cover material enters the gluing unit, it receives a precise coating of hot gelatin glue, ensuring uniform adhesion for a professional finish. With intuitive foot switches, operators effortlessly control the air suction plate, guaranteeing perfect registration of the cover material. Utilizing suction bars, the Pearl model automates the accurate placement of board pieces onto the cover material, enhancing efficiency and precision.

Following automatic board placement, the cover seamlessly transitions into the turning unit, where a meticulously designed process unfolds. Equipped with two turning units, the machine facilitates 2 side folding and 4 corner tucking in the first unit, followed by the completion of the remaining 2 side folding in the second unit. Additionally, the turning unit doubles as a calendaring unit, effectively removing air bubbles from the case before turning in.

Notably, our machine excels in versatility, effortlessly handling cases with central window cut-outs, ideal for photo album production. Upon completion, the final product smoothly exits to the rear of the machine on an inclined delivery table, marking the culmination of a meticulously crafted binding process. Experience efficiency, precision, and versatility with our cutting-edge Case Maker, redefining standards in binding technology.

- Compact & Ideal solution for Book Covers, Box Files, Photo Albums, Clip Pads, Game Boards, Photo Album window pasting & folding, Note Books, Diaries in different sizes. Easy format change over. Window pasting and folding also possible.

Active Pearl Features

- No adjustment necessary for size changes.

- Each cover can be a different size.

- Cost effective, simple and reliable.

- Exceptionally wide format range.

- Viscosity hot melt system.

- Auto delivery system.

Technical Data

| Min. case size | 150mm x 160mm |

| Max. case size | 450mm x 800mm |

| Paper thickness | 80gsm - 170gsm |

| Board thickness | 1.5mm - 5mm |

| Turning-in width | 15mm - 20mm |

| Production | 6 to 10 cases/min (Approx) |

| Glue | Hot/Cold (Optional) |

| Power | 7 HP, 3 Phase, 415 Volts |

| Dimensions | H 1650 mm x L2100 mm x W 1900 mm |

| Weight | 1000 Kgs. |

| Gluing System | Bottom |

| Man Power | One |

| Materials | Paper, Laminated Paper, Plastic-coated Paper, Cloth, etc. |