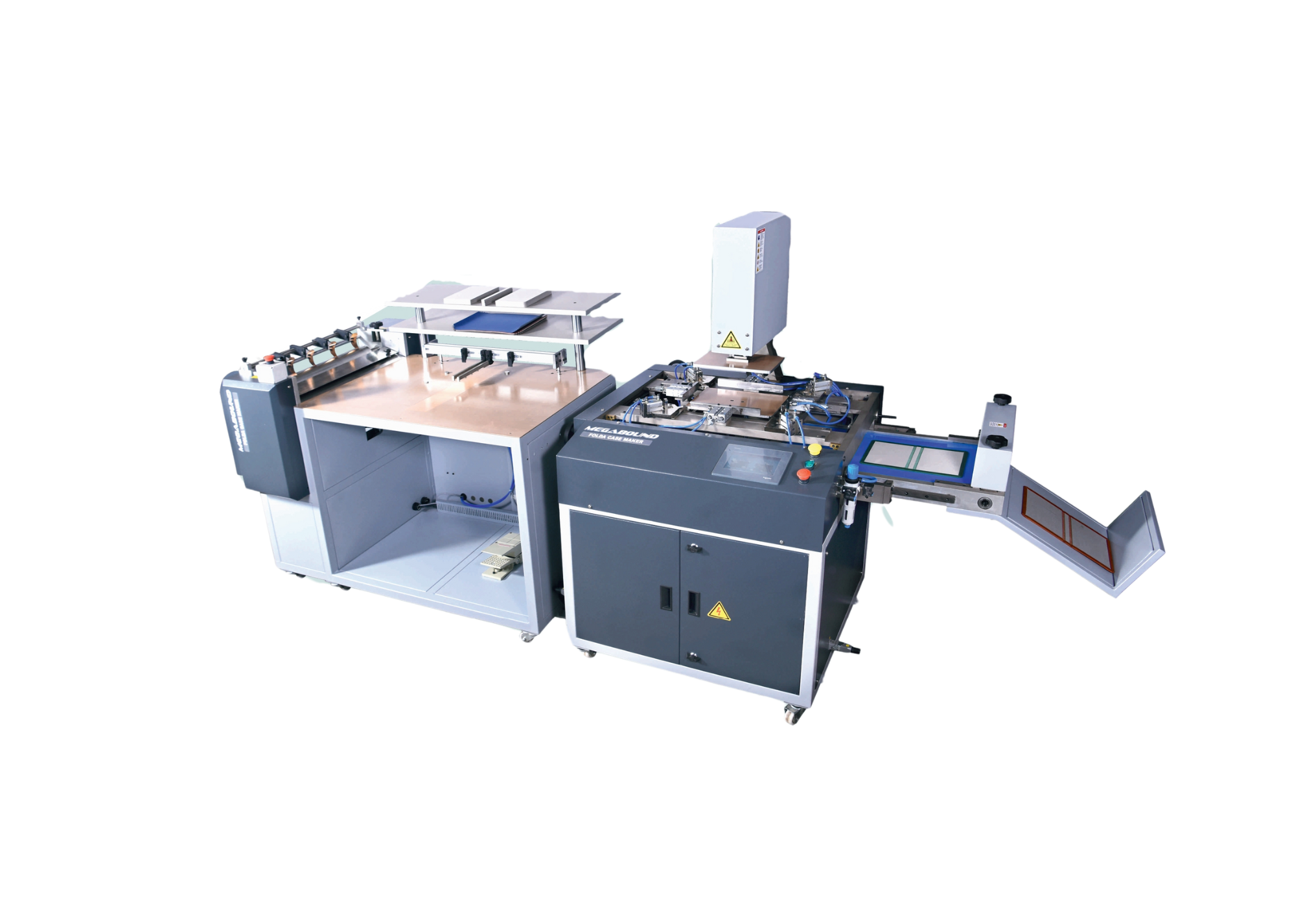

FOLDA CASEMAKER

Introducing the Megabound Gluing Unit with Board Fixing Unit, a robust solution for precise and efficient binding operations. As the operator guides the cover material into the gluing unit, it receives an even coating of hot gelatin glue, ensuring optimal adhesion. Utilizing intuitive foot switches, the operator controls the air suction plate for seamless registration of the cover material. With precision in mind, suction bars facilitate the manual placement of board pieces onto the cover material, guaranteeing accuracy with each placement.

The Megabound FOLDA Case Maker offers versatility in producing hard covers, case covers, box covers, and more. With automated folding of case edges, including round and square corner edges, this machine delivers exceptional results. Following folding, the case undergoes calendaring, accommodating various materials such as metallic-coated paper, PU leather, and laminated paper. From cosmetic box covers with mirrors to small cases for jewel boxes, the FOLDA machine adapts effortlessly, accommodating thicknesses ranging from 1mm to 8mm.

Experience unparalleled efficiency and versatility with the Megabound Gluing Unit with Board Fixing Unit and FOLDA Case Maker. Whether crafting intricate jewel box covers or robust hard covers, these machines deliver precise results, meeting the diverse needs of binding operations with ease.

Technical Data

| Min. case size | 50mm x 70mm (2″ x 3″) |

| Max. case size | 480mm x 350mm (18″ x 14″) |

| Cover thickness | 100-250gsm |

| Production | 10 to 15cases/min. (Approx) |

| Power Requirement | 3.5 kw |

| Air compressor | 6 Bar |

| Voltage | 440 volt, 3 phase |

| Machine Dimensions | 900 mm x 1320 mm x 1600 mm |

| Weight | 650 Kgs. |

| Glue | Hot melt |