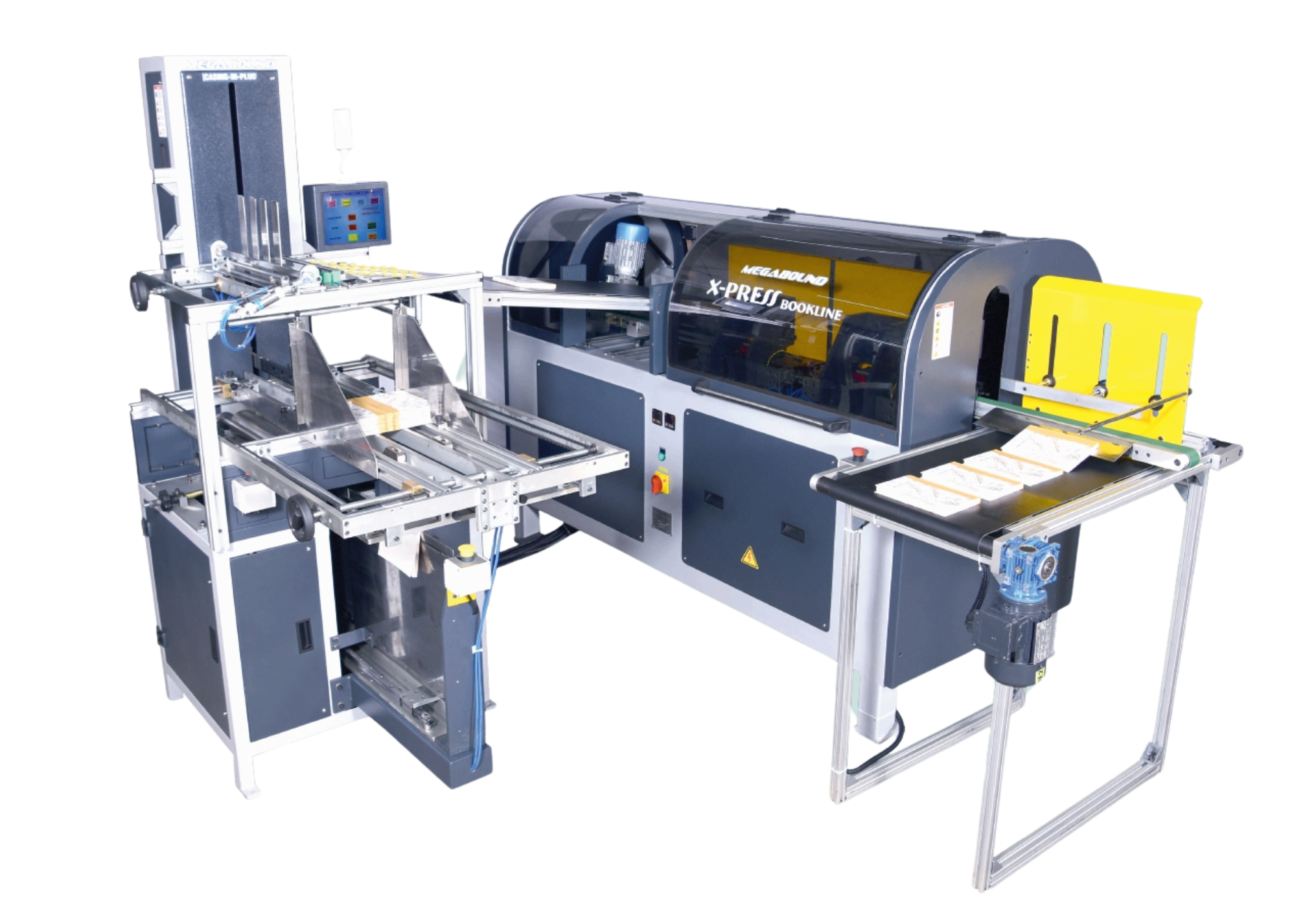

X-PRESS BOOK LINE

Online Casing in & Joint Forming

Introducing our Single-Person Operated Gluing Machine, an efficient and versatile solution for adhesive application across various materials. With the capability to use cold vinyl glue, this machine offers flexibility and adaptability, ensuring precise glue application on different substrates. The easily detachable glue tank facilitates hassle- free cleaning, maintaining optimal performance and longevity.

Following casing-in, each book is seamlessly transported along the conveyor to our hydraulic joint forming station. Here, every individual book undergoes joint forming twice in two stations, guaranteeing Impeccable results. Featuring easy operation and high performance, our machine offers uniform adhesive application with its three-roller format and auto adjustability for any book format. Additionally, it can handle flexible covers and extremely small formats with ease, ensuring efficient production.

Equipped with advanced features such as automatic book feeding and a hydraulic book press of 2 tons for even pressing, our machine delivers exceptional results consistently. With 2 station online hydraulic joint forming, adjustable depth on joint forming, and heated formers for perfect joint formation, it offers unmatched versatility and precision. Experience convenience, reliability, and efficiency with our Single- Person Operated Gluing Machine, designed to meet the diverse needs of modern production environments.

- Easy operation that offers high performance.

- Uniform adhesive application with three-roller format.

- Auto-adjustability for any book format.

- Can handle flexible covers and extremely small formats.

- Automatic book feeding.

- Hydraulic book press of 2 ton for even pressing of book.

- 2 station online hydraulic joint forming.

- Adjustable dept on joint forming.

- Heated formers for perfect joint formation.

- Interchangeable guides for various applications.

- Individual book gets 2 times pressing in 2 stations.

- Auto cover feeding

Technical Data

| Min. book format | 100 mm x 150 mm |

| Max. book format | 360 mm x 350 mm |

| Min. book thickness | 5 mm |

| Max. book thickness | 60 mm |

| Production | 5 to 10 books/min (Approx) |

| Book Size | 360 mm x 350 mm |

| Power | 7 HP, 3 Phase, 415V |

| Dimensions | L 2400 x W 2300 x H 1700 |

| Weight | 1200 Kgs. |

| Hydraulic Pressure | 2000 Kgs |